Floating Fish Feeds Machine1 IntroductionTwin screw fish feed extruder adopts advanced production technology at home and abroad, with stable operation, large output, simple operation and reasonable final product quality.

Связаться сейчас

Floating Fish Feeds Processing Machine1.IntroductionMain features of wet type floating fish pellet machine:1. The feeding, rotary cutting and main drive all adopt frequency conversion speed regulation system, which has strong power, stable operation, energy saving, high aquatic production efficiency, sturdy and durable wet type floating fish pellet machine, low failure rate, and convenient operation and maintenance.2.

Связаться сейчас

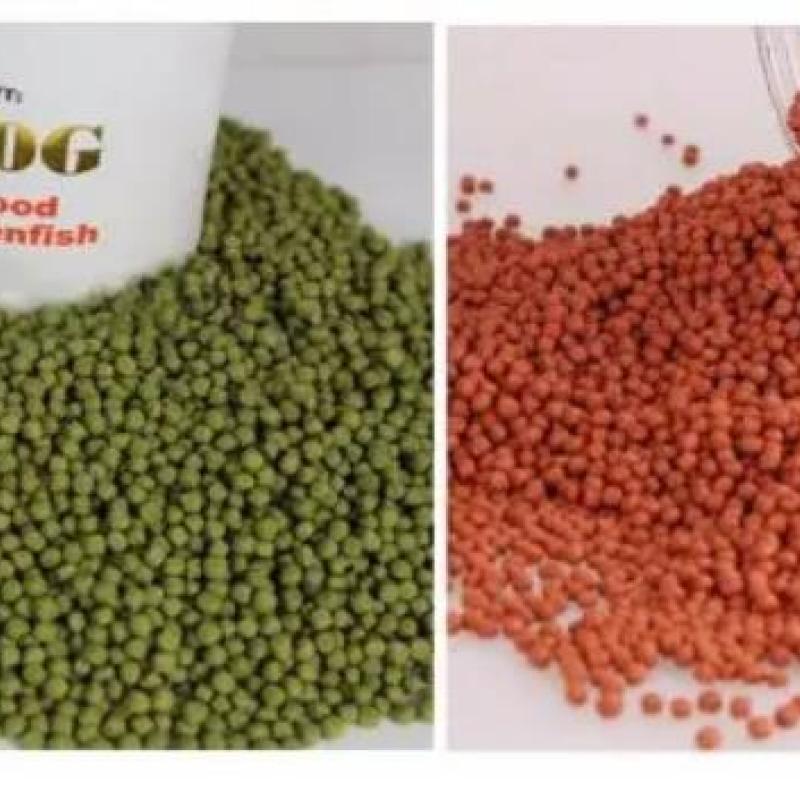

Fish Food Production Line1.IntroductionSpecially used inside the production and processing of numerous floating and sinking aquatic feeds, particularly suitable for the production of numerous floating aquatic feeds, and additionally extensively used in the production and processing of pet meals.2.Production Video3.Machine display 4.Samples 5.Technical parameterModelCapacity/outputMain MotorFeeder MotorScrew DiameterCutter MotorDimensionBRT4040-50kg/h5.5kw(220V)0.4kwΦ400.4kw1.36*1.60*0.85mBRT60100-150kg/h15kw0.4kwΦ600.4kw1.36*1.67*0.85mBRT70180-250kg/h18.5kw0.4kwΦ700.4kw1.

Связаться сейчас

Fish Feed Manufacturing Machine1 IntroductionHigh-protein extruded feed pellets, immoderate protein content, fish develop speedy, soak up nicely, and the degree of feed waste is low, and fish excretion has less harm to water fine, and can be recycled and used to increase ecological agriculture.

Связаться сейчас

Simple Structure Fish Feed Pellet Making Machine 1 IntroductionSimple operation automatic fish production line is widely used for producing grains into high grade aquatic feed pellets for fish,catfish,shrimps,crabs,etc.

Связаться сейчас

Fish Feed Extruder Machine Prices1 IntroductionThe fish feed market has continued to grow in recent years. In order to be more suitable for the feeding and growth of fish, fish feed pellets need to be stable in nature and rich in nutrients.

Связаться сейчас

Fish Feed Machine Line1 IntroductionOur fish feed machine can yield up to 100 kg per hour - 10 tons per hour, divided into specific equipment configuration. When fish were fed high protein extruded feed pellets with high protein content, fish developed rapidly and absorbed efficiently.From raw food to cooked food, from shallow processing to deep processing, from the initial feeding of fish and shrimp, and then to the mature pellet feeding, and now to the scientific feeding of nutrition ratio, fish feed types and feeding methods have changed.

Связаться сейчас

Big Capacity Fish Food Production Machine1.IntroductionSpecially used inside the production and processing of numerous floating and sinking aquatic feeds, particularly suitable for the production of numerous floating aquatic feeds, and additionally extensively used in the production and processing of pet meals.2.Production Video3.Machine display 4.Samples 5.Technical parameterModelCapacity/outputMain MotorFeeder MotorScrew DiameterCutter MotorDimensionBRT4040-50kg/h5.5kw(220V)0.4kwΦ400.4kw1.36*1.60*0.85mBRT60100-150kg/h15kw0.4kwΦ600.4kw1.36*1.67*0.85mBRT70180-250kg/h18.5k

Связаться сейчас

Fish Food Production Line1.IntroductionSpecially used inside the production and processing of numerous floating and sinking aquatic feeds, particularly suitable for the production of numerous floating aquatic feeds, and additionally extensively used in the production and processing of pet meals.2.Production Video3.Machine display 4.Samples 5.Technical parameterModelCapacity/outputMain MotorFeeder MotorScrew DiameterCutter MotorDimensionBRT4040-50kg/h5.5kw(220V)0.4kwΦ400.4kw1.36*1.60*0.85mBRT60100-150kg/h15kw0.4kwΦ600.4kw1.36*1.67*0.85mBRT70180-250kg/h18.5kw0.4kwΦ700.4kw1.

Связаться сейчас

Fish Feed Extruder Machine Prices1 IntroductionThe fish feed market has continued to grow in recent years. In order to be more suitable for the feeding and growth of fish, fish feed pellets need to be stable in nature and rich in nutrients.

Связаться сейчас

Dry Floating Fish Feed Pellet Extruder Machine1 Introduction High-protein extruded feed pellets, high-protein content material, fish develop quickly, absorb well, and feed waste is minimal, and fish excrement does less harm to high-quality water, and may be recycled and utilized to increase ecological agriculture.

Связаться сейчас

Sinking Fish Feed Machine 1.IntroductionThe forms of fish feed have prolonged past through a way from raw to cooked, from shallow processing to deep processing, from the actual fish and shrimp beaten right now to feeding, to the later matured pellet feeding, to the modern-day nutrient ratio clinical feeding. the extruded fish feed machine and device manufacturing line specializes in the manufacturing of numerous sorts and specifications of extruded aquatic fish feed for small and medium aquaculture farms and character fisheries.

Связаться сейчас

Dog Food Pellet Making Line Machine1 IntroductionDog Food Pellet Making Line Machine line makes use of grain pellets or powders as uncooked substances and consists of many processes. Mixing, extruding, drying, flavoring and cooling etc.

Связаться сейчас

Fish Feed Production Machine1.IntroductionMain factors of Fish Feed Production Machine:1. Fish Feed Production Machine all undertake frequency conversion tempo insurance policies system, which has sturdy power, every day operation, electrical electrical energy saving, immoderate aquatic manufacturing efficiency, sturdy and extended lasting Fish Feed Machine Extruder, low failure rate, and reachable operation and maintenance.2.

Связаться сейчас

Dog Food Extruder1.IntroductionMainly used in the production and processing of various floating and sinking aquatic feeds, especially suitable for the production of various floating aquatic feeds, and also widely used in the production and processing of pet food.2.Production Video3.Machine display 4.Samples 5.Technical parameterModelCapacity/outputMain MotorFeeder MotorScrew DiameterCutter MotorDimensionBRT4040-50kg/h5.5kw(220V)0.4kwΦ400.4kw1.36*1.60*0.85mBRT60100-150kg/h15kw0.4kwΦ600.4kw1.36*1.67*0.85mBRT70180-250kg/h18.5kw0.4kwΦ700.4kw1.36*1.67*0.85mBRT80250-300kg/h22kw

Связаться сейчас

Electric Fish Feed Make Machine1.IntroductionEquipment composition of Electric Fish Feed Make Machine: fish feed mixer → fish feed feeder → working platform → fish feed pellet extruder laptop → excessive stress air feeder → fish feed oven → hoist → seasoning line → cooling conveyor.

Связаться сейчас

Dry Food Machine For Dog1 IntroductionDry Food Machine For Dog makes use of grain pellets or powders as raw elements and consists of many processes. Puffing is an vital hyperlink in the method of canine meals processing, and the enlargement method is additionally a procedure of canine meals uncooked fabric molding.

Связаться сейчас

Exstruded Fish Feed Machine1.IntroductionMain aspects of Exstruded Fish Feed Machine:1. The feeding, rotary cutting and essential strength all undertake frequency conversion pace regulation system, which has sturdy power, constant operation, energy saving, immoderate aquatic manufacturing efficiency, sturdy and lengthy lasting Double Screw Fish Feed Machine, low failure rate, and accessible operation and maintenance.2.

Связаться сейчас

Dog Food Extruder1.IntroductionMainly used in the production and processing of various floating and sinking aquatic feeds, especially suitable for the production of various floating aquatic feeds, and also widely used in the production and processing of pet food. In the single screw extrusion cavity, the material is basically closely around the screw, a continuous ribbon in a spiral shape.

Связаться сейчас

Kurkure Making Machine Manufactures1.IntroductionKurkure Making Machine Manufactures is made of corn residue as uncooked material, extruded with the useful resource of way of the host laptop computer into irregular puffed food, after seasoning can be made into top notch trend products, cherished with the aid of capability of consumers. The Kurkure Making Machine Manufactures feeds the hopper with the aid of vibration and can alter the glide value of uncooked materials.

Связаться сейчас

Automatic Fish Feed Making Machine1 IntroductionThe varieties of fish feed have handed by a manner from uncooked to cooked, from shallow processing to deep processing, from the proper fish and shrimp crushed barring prolong to feeding, to the later matured pellet feeding, to the modern-day nutrient ratio clinical feeding. Automatic Fish Feed Making Machine extruded fish feed tools and computing device manufacturing line,specializes in the manufacturing of severa sorts and specs of extruded aquatic fish feed for small and medium aquaculture farms and fisheries.

Связаться сейчас

Twin Screw Fish Feed Extruder1.IntroductionMain elements of Twin Screw Fish Feed Extruder:1. The feeding, rotary reducing and quintessential power all undertake frequency conversion tempo regulation system, which has sturdy power, regular operation, electrical electricity saving, immoderate aquatic manufacturing efficiency, sturdy and extended lasting Double Screw Fish Feed Machine, low failure rate, and on hand operation and maintenance.2.

Связаться сейчас

Animal Feed Fish Making Machine1 IntroductionTwin screw fish feed extruder is an automatic production line from mixing to packaging. The production capacity is as high as 5-7 tons per hour, which can produce high-quality fish feed. The integrated control cabinet makes the operation easier and easy to learn.

Связаться сейчас

Dog Food Extruder Machine1 IntroductionDog Food Extruder Machine makes use of grain pellets or powders as uncooked substances and consists of many processes. Puffing is an important link in the process of dog food processing, and the expansion process is also a process of dog food raw material molding. During the molding process, water is added in the form of steam to make the raw material starch in dog food gelatinize, and the temperature rises to 100 ℃~180 ℃.

Связаться сейчас