Bread Crumb Extruder Machine1.Introduction The producing line makes use

Связаться сейчас

Extruded Bread Crumbs Processing Line1.Introduction Extruded bread crumbs pro

Связаться сейчас

Panko Bread Crumbs Machine1.Introduction Panko Bread Crumbs Machine makes use

Связаться сейчас

Bread Crumbs Production Line1.Introduction The manufacturing line uses flour

Связаться сейчас

Automatic Bread Crumbs Production Line1.Introduction The Automatic Bread Crum

Связаться сейчас

Automatic Panko Bread Crumbs Machines1.Introduction The producing line makes

Связаться сейчас

Tortilla Chips Processing Extruder1.IntroductionThe Nachos/Doritos/Tortilla manufacturing line is made of corn flour after extrusion, molding and frying. Tortilla Chips Processing Extruder predominant factors are corn meal, water, vegetable oil and salt. After frying, spray on the ground with vary of flavoring powder. Because of its crisp and delicious, it is cherished with the aid of early life and adults.

Связаться сейчас

Bread Crumbs Making Machine1.Introduction The producing line uses flour and s

Связаться сейчас

Bread Crumbs Production Line1.Introduction The production line uses flour and

Связаться сейчас

Puff Bread Crumbs Making Machine1.Introduction Puff bread crumbs making machi

Связаться сейчас

Tortilla Chips Processing Machine1.IntroductionThe Nachos/Doritos/Tortilla manufacturing line is made of corn flour after extrusion, molding and frying. Tortilla Chips Processing Machine predominant elements are corn meal, water, vegetable oil and salt. After frying, spray on the floor with a range of flavoring powder. Because of its crisp and delicious, it is cherished via youth and adults.

Связаться сейчас

Fortified Rice Processing Line Machinery1.IntroductionFortified rice processing line machinery makes use of damaged rice as uncooked material, and grinds damaged rice via the pulverization technique to turn out to be satisfactory rice noodles. The extruder of Fortified rice processing line machinery adopts twin-screw configuration and is made of alloy cloth with the aid of specific process, so it has a lengthy carrier life. Fortified rice processing line machinery has a circulating water cooling gadget to make certain that the product is out of the mold.

Связаться сейчас

Kurkure Processing Making Machine1.IntroductionCheeto Kurkure is a special puffed and extruded food with a crisp texture. Corn flour or grits are mixed with a certain proportion of water and put into cheeto single screw extruder. Squeezed and kneaded by the extruder's two turntables, the meal forms irregular, twisted shapes, which are then cut to the desired length by a cutter. Cheetos can be fried or baked for flavor.

Связаться сейчас

Automatic Pet Food Processing Machine1.Introduction The Automatic Pet Food Processing Machine makes powdered raw resources which consists of corn flour into puppies substances through the approach of blending,extruding,drying,flavoring and cooling. the Automatic Pet Food Processing Machine can produce doggies elements of a range of sizes and styles.

Связаться сейчас

Kurkure Cheetos Complete Processing Plant1.IntroductionCheetos are a special kind of squeeze food that has a crunchy texture. Grits are mixed with a certain proportion of water and enter the extruder. Under the action of extrusion and kneading by the two turntables of the extruder, the corn kernels form irregular and twisted shapes, and then they are cut to the required length by the cutter, and then the finished oil is fried and flavoured and packaged for sale.

Связаться сейчас

Fried Snacks Processing Line1.IntroductionIn recent years, fried snacks have become very popular, and various shapes and flavors are very popular among consumers.

Связаться сейчас

Corn Puffs Snack Processing Line1 Introduction The Corn Puffs Snack Processing Line makes powdered raw elements which consist of corn flour into puff snack through capacity of the laptop computer of mixing,puffing,drying,flavoring and cooling. the equal manufacturing line can produce puff snacks of a fluctuate patterns and sizes.

Связаться сейчас

Baked Tortilla Doritos Chips Processing Extruder1.IntroductionThe Nachos/Doritos/Tortilla line is made from corn flour that is extruded, molded, fried or baked. Its main ingredients are corn meal, water, vegetable oil and salt. After extrusion by puffing machine, baking or frying, spraying various flavoring powder on the surface, can produce different flavors of delicious snacks. Children and adults alike love it because it is crispy and delicious.

Связаться сейчас

Artificial Rice Processing Line1.IntroductionUsing Artificial Rice Processing Line, the broken rice (damaged rice and fallen rice embryo) may additionally be restored, restored or processed into rice grains which can be nearly the equal as every day whole rice, or in step with the necessities of scientific foods plan, a few natural dietary nutritional vitamins alongside with extra than a few varieties miscellaneous grains are blended together in a superb share to make excessive-nutrition rice and proper now rice with the equal cooking regular common overall performance and cooking strategy (wi

Связаться сейчас

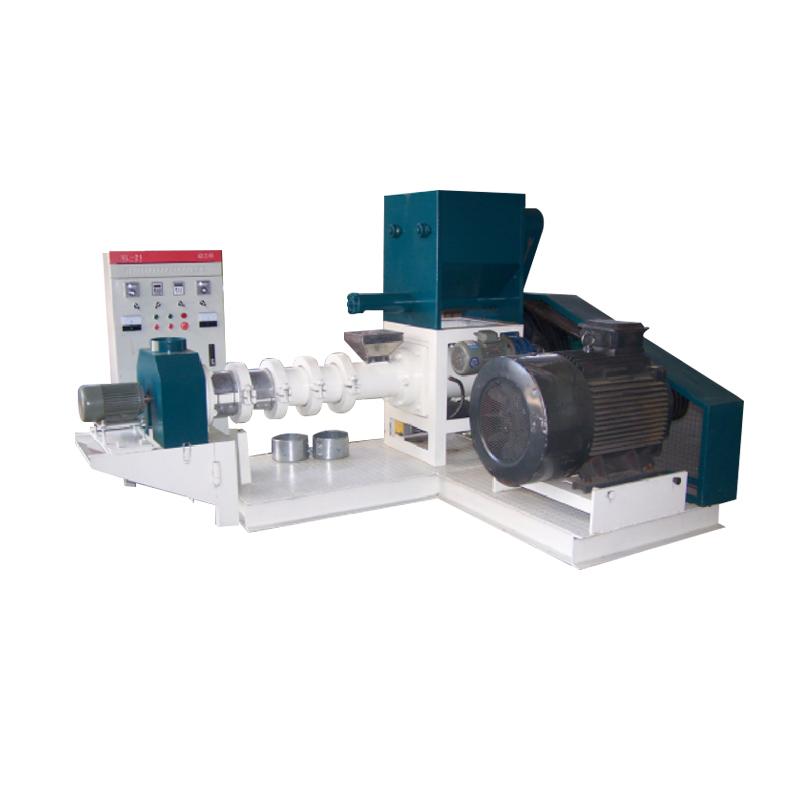

Agricultural Fish Feed Processing Plant Machinery1 IntroductionFrom raw food to cooked food, from shallow processing to deep processing, from the initial feeding of fish and shrimp, and then to the mature pellet feeding, and now to the scientific feeding of nutrition ratio, fish feed types and feeding methods have changed. For small and medium-sized farms and characteristic fisheries, the extruded fish feed equipment production line specializes in producing various types and specifications of extruded fish feed.

Связаться сейчас

Double Screw Bread Crumb Making Machine1.Introduction The manufacturing line

Связаться сейчас

Kurkure Complete Processing Plant1.IntroductionCheeto Kurkure is a special puffed and extruded food with a crisp texture. Corn flour or grits are mixed with a certain proportion of water and put into cheeto single screw extruder. Squeezed and kneaded by the extruder's two turntables, the meal forms irregular, twisted shapes, which are then cut to the desired length by a cutter. Cheetos can be fried or baked for flavor.

Связаться сейчас

Big Capacity Dog Food Extruder 1.IntroductionMainly used in the production and processing of various floating and sinkingfeeds, specially appropriate for the manufacturing of various floating aquatic feeds, and additionally extensively used in the production and processing of pet food.2.Production Video3.Machine display 4.Samples 5.Technical parameterModelCapacity/outputMain MotorFeeder MotorScrew DiameterCutter MotorDimensionBRT4040-50kg/h5.5kw(220V)0.4kwΦ400.4kw1.36*1.60*0.85mBRT60100-150kg/h15kw0.4kwΦ600.4kw1.36*1.67*0.85mBRT70180-250kg/h18.5kw0.4kwΦ700.4kw1.36*1.

Связаться сейчас

Macaroni Making Line1.IntroductionSingle-screw pasta macaroni processing line adopts the semolina,wheat flour, corn starch and potato starch because the raw material then form a sort of enjoyment meals after extruding, slaking, forming and drying. numerous shapes of pasta macaroni may be made via this line honestly changing the dies of extruder.

Связаться сейчас